Cooling Vests and Mats for Pets: Keeping Them Comfortable

Materials and Durability: Ensuring Long-Lasting Cooling Comfort

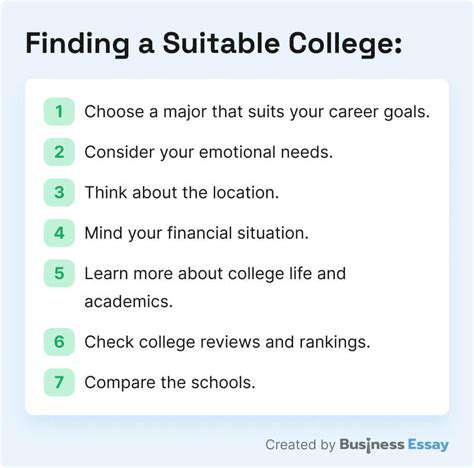

Choosing the Right Materials

Selecting the appropriate materials is crucial for ensuring the longevity and performance of any product. Different materials possess unique properties, such as strength, flexibility, and resistance to various environmental factors. Understanding these properties allows manufacturers to make informed decisions about the materials they use, ultimately impacting the product's durability and overall lifespan. For example, choosing a material that is resistant to water damage is essential for outdoor furniture or building materials. Selecting a durable material for a high-traffic area will ensure the product can withstand everyday use and maintain its integrity over time. This careful consideration of material selection is paramount for creating a product that meets the needs of consumers and stands the test of time.

Material selection also plays a vital role in the product's aesthetic appeal. Different materials evoke different feelings and perceptions. For example, natural materials like wood or stone often convey a sense of warmth and authenticity. Metals, on the other hand, often symbolize strength and sophistication. Furthermore, the choice of material can impact the overall cost of production, making it an important factor in the design process. The combination of aesthetics, durability, and cost-effectiveness is key when selecting the right materials for a product. Finding the perfect balance is essential for creating successful products.

Durability Testing and Standards

Rigorous testing is essential to assess the durability of any material or product. Durability tests simulate real-world conditions to determine how well a product withstands various stresses and strains. This process helps manufacturers understand the limitations of their product and identify potential weaknesses. Extensive testing of materials and products under different conditions, including extreme temperatures, high-impact forces, and prolonged exposure to harsh elements, is an essential part of the quality control process. This ensures that the product meets industry standards and consumer expectations.

Industry standards and certifications, such as ASTM International standards, play a critical role in ensuring the quality and durability of products. These standards set minimum requirements for material properties and product performance. Adherence to these standards helps ensure consumer safety and trust. By adhering to these standards, manufacturers demonstrate their commitment to producing reliable and durable products, fostering a culture of trust and confidence in the industry.

Furthermore, understanding the potential failure modes of a material or product is critical for developing effective strategies to improve durability. Analyzing the results of various tests allows engineers to identify areas that require enhancement. This knowledge allows for the development of improved designs, leading to more resilient and long-lasting products. By continuously evaluating and improving upon existing designs, manufacturers can ensure that their products meet or exceed the expectations of consumers and maintain a leading position in the market.

Read more about Cooling Vests and Mats for Pets: Keeping Them Comfortable

Hot Recommendations

- Holistic Pet Health: Integrating Approaches

- The Future of Pet Identification: Biometric Scanners

- Service Dogs for PTSD: A Guide to Support

- The Benefits of Non Anesthetic Professional Teeth Cleaning

- Herbal Supplements for Pet Joint Health

- The Intersection of IoT and Pet Wellness

- Healthy Weight Management for Senior Pets

- The Best Pet Beds for Orthopedic Support and Comfort

- Competitive Dog Sports: Agility, Flyball, Dock Diving

- Luxury Pet Hotels: Pampering Your Beloved Pet